We use gadgets every day, but do we know how they are made? What are the steps and processes involved in creating the devices that we rely on for communication, entertainment, work, and more? In this blog post, we will reveal the secrets behind the scenes of how gadgets are made, from the initial design to the final testing.

Designing Gadgets

The first step in making a gadget is to design it. This is where the idea and vision of the gadget are born. Designers have to consider various factors, such as the purpose, function, appearance, usability, and marketability of the gadget. They also have to research the existing and potential competitors, customers, and trends in the industry.

Tools and Software for Designing Gadgets

Designers use various tools and software to create and test their designs, such as CAD (computer-aided design), 3D printing, and simulation. CAD allows designers to create digital models of the gadget and modify them easily. 3D printing allows designers to print physical prototypes of the gadget and test them in real life. Simulation allows designers to test the performance and behavior of the gadget in different conditions and scenarios.

Some of the most popular and widely used tools and software for designing gadgets are:

- Autodesk: A software company that offers a range of CAD and 3D design products, such as AutoCAD, Fusion 360, Inventor, and Maya. Autodesk is used by many professionals and hobbyists in various fields, such as engineering, architecture, animation, and gaming.

- SolidWorks: A software product that provides a complete 3D design solution, from sketching to manufacturing. SolidWorks is used by many engineers and designers to create and test mechanical, electrical, and industrial gadgets, such as robots, drones, and cars.

- Blender: A free and open-source software that provides a comprehensive 3D creation suite, from modeling to rendering. Blender is used by many artists and enthusiasts to create and test artistic and creative gadgets, such as sculptures, toys, and jewelry.

Iterations and Feedback Loops for Designing Gadgets

Designers have to go through several iterations and feedback loops to refine their designs until they meet the desired specifications and user needs. They have to balance the trade-offs between the cost, quality, and time of the gadget. They also have to comply with the legal and ethical standards and regulations of the industry.

Some of the most common and effective methods for iterating and getting feedback on gadget designs are:

- User Testing: A method that involves testing the gadget with real or potential users and observing their reactions, behaviors, and opinions. User testing helps designers to evaluate the usability, functionality, and desirability of the gadget. User testing can be done in various ways, such as interviews, surveys, focus groups, and usability tests.

- Prototyping: A method that involves creating a simplified or partial version of the gadget and testing it with users or stakeholders. Prototyping helps designers to validate the concept, feasibility, and viability of the gadget. Prototyping can be done in various stages, such as low-fidelity, medium-fidelity, and high-fidelity.

- A/B Testing: A method that involves creating two or more versions of the gadget and testing them with users or stakeholders. A/B testing helps designers to compare and contrast the performance, impact, and preference of the gadget. A/B testing can be done in various ways, such as split testing, multivariate testing, and factorial testing.

Manufacturing Gadgets

The next step in making a gadget is to manufacture it. This is where the components and parts of the gadget are produced and assembled. Manufacturers have to source the materials, equipment, and labor needed to make the gadget. They also have to optimize the production process, such as the speed, efficiency, and accuracy of the gadget.

Machines and Methods for Manufacturing Gadgets

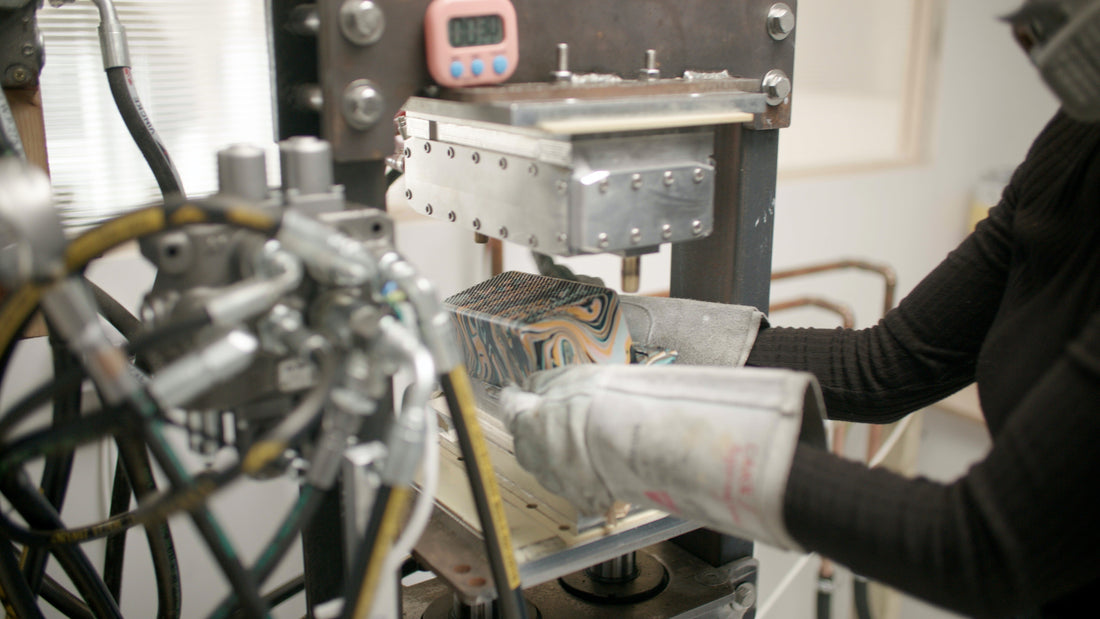

Manufacturers use various machines and methods to make gadgets, such as injection molding, CNC (computer numerical control) machining, soldering, and laser cutting. Injection molding allows manufacturers to produce large quantities of plastic parts by injecting molten plastic into a mold. CNC machining allows manufacturers to produce precise and complex metal parts by using a computer-controlled machine. Soldering allows manufacturers to join electrical components by melting and solidifying a metal alloy. Laser cutting allows manufacturers to cut and engrave materials by using a high-powered laser beam.

Some of the most advanced and innovative machines and methods for manufacturing gadgets are:

- 3D Printing: A machine and method that allows manufacturers to produce complex and customized parts by depositing layers of material on top of each other. 3D printing can use various materials, such as plastic, metal, ceramic, and even biological. 3D printing can create gadgets that are impossible or difficult to make with traditional methods, such as organs, food, and clothing.

- Nanotechnology: A machine and method that allows manufacturers to manipulate matter at the atomic and molecular level. Nanotechnology can create gadgets that are extremely small, powerful, and efficient, such as sensors, batteries, and chips. Nanotechnology can also create gadgets that have new and unique properties, such as self-healing, self-cleaning, and self-assembling.

- Biotechnology: A machine and method that allows manufacturers to use living organisms or their components to make gadgets. Biotechnology can create gadgets that are organic, sustainable, and adaptable, such as biofuels, bioplastics, and biomedicines. Biotechnology can also create gadgets that are inspired by nature, such as biomimicry, bioart, and biodesign.

Quality and Consistency for Manufacturing Gadgets

Manufacturers have to ensure the quality and consistency of the gadget throughout the production process. They have to inspect and test the components and parts for any defects or errors. They also have to follow the safety and environmental standards and regulations of the industry.

Some of the most common and effective tools and techniques for ensuring quality and consistency in manufacturing gadgets are:

- Six Sigma: A tool and technique that aims to reduce the variation and defects in the production process by using data and statistics. Six Sigma follows a structured and systematic approach, such as DMAIC (Define, Measure, Analyze, Improve, Control) or DMADV (Define, Measure, Analyze, Design, Verify). Six Sigma helps manufacturers to improve the quality, efficiency, and profitability of the gadget.

- Lean Manufacturing: A tool and technique that aims to eliminate the waste and inefficiency in the production process by using the principles of value, flow, pull, and perfection. Lean manufacturing follows a continuous and iterative approach, such as PDCA (Plan, Do, Check, Act) or Kaizen (Continuous Improvement). Lean manufacturing helps manufacturers to reduce the cost, time, and resources of the gadget.

- ISO 9001: A tool and technique that aims to establish the standards and requirements for the quality management system of the production process. ISO 9001 follows a customer-oriented and process-based approach, such as Plan, Do, Check, Act (PDCA). ISO 9001 helps manufacturers to meet the expectations and needs of the customers and the market.

Testing Gadgets

The final step in making a gadget is to test it. This is where the quality, functionality, and safety of the gadget are verified and validated. Testers have to check if the gadget meets the expectations and requirements of the customers and the market. They also have to identify and fix any issues or problems that may arise with the gadget.

Tools and Techniques for Testing Gadgets

Testers use various tools and techniques to test gadgets, such as software, hardware, sensors, and human trials. Software allows testers to test the logic, code, and algorithms of the gadget. Hardware allows testers to test the physical, mechanical, and electrical aspects of the gadget. Sensors allow testers to test the temperature, humidity, vibration, and other environmental factors of the gadget. Human trials allow testers to test the user experience, feedback, and satisfaction of the gadget.

Some of the most popular and widely used tools and techniques for testing gadgets are:

- JUnit: A software tool and technique that allows testers to write and run unit tests for Java-based gadgets. JUnit is a framework that provides annotations, assertions, and runners to create and execute test cases. JUnit helps testers to verify the correctness and functionality of the gadget.

- Arduino: A hardware tool and technique that allows testers to create and control electronic gadgets. Arduino is a platform that consists of a board, a software, and a library that enable testers to program and interact with the gadget. Arduino helps testers to prototype and experiment with the gadget.

- Raspberry Pi: A hardware tool and technique that allows testers to create and control smart gadgets. Raspberry Pi is a computer that can be connected to various devices, such as sensors, cameras, and displays. Raspberry Pi helps testers to explore and innovate with the gadget.

Types of Tests for Testing Gadgets

Testers have to conduct various types of tests, such as unit tests, integration tests, system tests, and acceptance tests. Unit tests test the individual components or functions of the gadget. Integration tests test the interaction and compatibility of the components or functions of the gadget. System tests test the overall performance and behavior of the gadget. Acceptance tests test the compliance and suitability of the gadget for the customers and the market.

Some of the most common and effective examples of tests for testing gadgets are:

- Stress Test: A type of test that tests the durability and reliability of the gadget under extreme or abnormal conditions, such as high temperature

, high pressure, or high load. Stress test helps testers to evaluate the robustness and stability of the gadget.

- Usability Test: A type of test that tests the ease of use and learnability of the gadget by real or potential users. Usability test helps testers to evaluate the user interface, user experience, and user satisfaction of the gadget.

- Security Test: A type of test that tests the protection and privacy of the gadget from unauthorized access or attack. Security test helps testers to evaluate the encryption, authentication, and authorization of the gadget.

Conclusion

As you can see, making a gadget is not a simple task. It requires a lot of creativity, skill, and effort from various people and teams. It also involves a lot of challenges, risks, and uncertainties. The next time you use a gadget, you might appreciate it more knowing how it was made. We hope you enjoyed this blog post and learned something new. If you have any questions or comments, please feel free to leave them below. Thank you for reading!